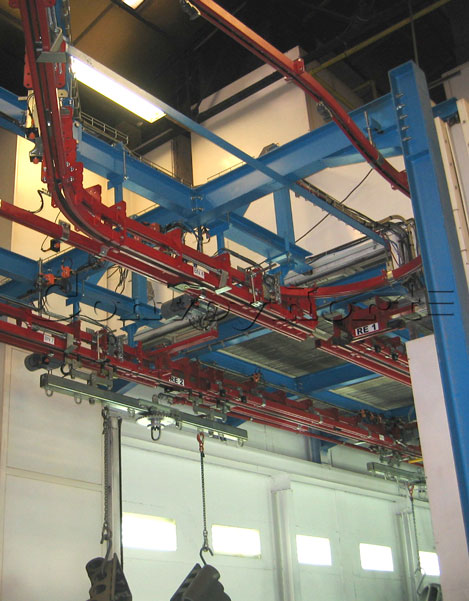

The 3500 series poweer and free conveyor includes 2 tracks one on top of the other.

Upper track section: 60mm×68mm×thickness 4mm.

Lower track section: 100mm×72mm×thickness 6mm.

Trolleys with rollings with steel bearings.

Maximum operating temperature: 250°C.

The distinctive feature of CONVOYNORT's power and free conveyors is their easy driving and accumulation mode.

The 3500 series power and free overhead conveyor allows the accumulation of the carriers. In line, at an angle or on parallel tracks, our storage areas are motorised by the same power and free drive chain. (See buffer area video)

Storage area at an angle

Accumulation area on parallel tracks

Storage area in an oven

Straight-line storage area

Straight-line storage area

Stop station of the carriers prior to automatic introduction in a motorised curtain paint booth.

Automatic rotating station.

ATEX area. Parallel elevator in a liquid paint booth.

Carrier accumulations in inventory areas are managed by stop stations connected to the conveyor robot.

CONVOYNORT on request includes the system automation. The summary, time management, operating modes, etc. are displayed on a screen.

CONVOYNORT trains maintenance personnel and users.