Overhead conveyor - Manual monorail - 500 series - Organization of workstation with a manual monorail 500 series

Overhead conveyor - Manual monorail - 500 series - Travelling bridge crane for a surface treatment installation

Overhead conveyor - Manual monorail - 500 series - Storage area for tire treatment

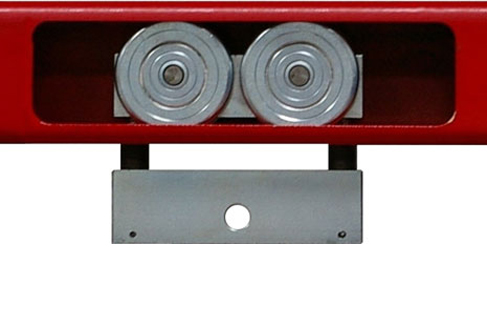

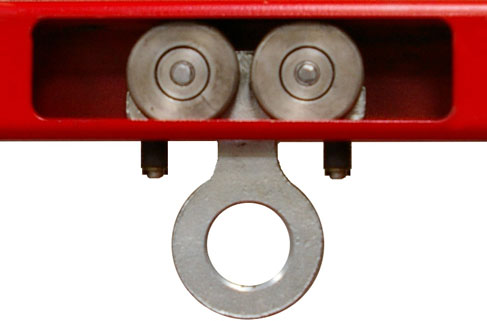

Rail section: 60mm×68mm×thickness 4mm.

Trolleys with steel bearing rollers.

Maximum operating temperature: 250°c.

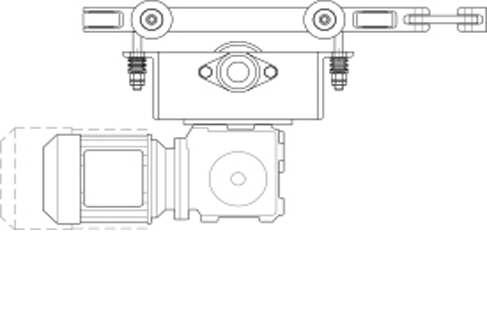

The 500 series manual monorail can be motorised on some sections (including switches) thanks to a side motor. For longer motorised sections, it can also receive a trolley drive chain

(see 3000 series power and free).

Brochure manual monorail 500 series

Stainless steel rails and trolleys can be provided. (See manual monorail stainless steel 500 Series)

Basic trolley

Short trolley

Hoist trolley

Motorized trolley

Long trolley 600mm

Long trolley 1000mm

Specific equipment can be made on request. For example : integration of special lifting systems, weighing, load bars for transported parts etc.

Turning switch plate.

To make operator movements easier, the turning section of the switch can be controlled automatically with a cylinder.

Switch motorisation on a manual conveyor.

The manual conveyor can be motorised in some areas.

Here on 2 parallel tracks with a side motor switch to jog the load bars forward.

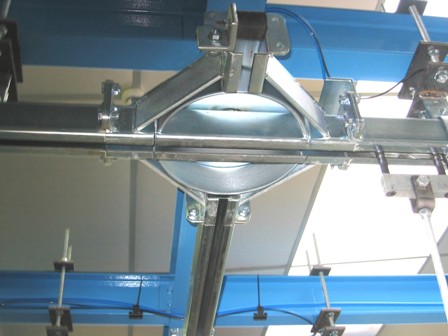

The retractable track may be a conveying solution through an airtight door. The retractable track is a simple answer for continuity of the handling circuit through an airtight door, a curtain door or a fire door. All doors which require a tight closing between two areas or premises. But also have to let work pieces to travel through being conveyed by an overhead conveyor.

Picture: 3 combined retractable rails closed and open, located at the front door of a high temperature curing oven.

Upward and downward elevators are used for level changes, and make loading and unloading easier.

The drop section is fitted with a pneumatic or electric hoist.

For light loads, lifting device can receive a pneumatic cylinder, in some cases.

Conveyor carriers for cooking furnace, handled with a perch.

Hoist travelling crane on a travelling platform can complement the manual conveying system.

The manual monorail can be used as a travelling bridge crane. Here, to introduce several loads at the same time in a curing oven, to reduce the door opening time.

In some cases, the system can be set up as a gravity conveyor.

CONVOYNORT can handle all of the client’s needs in terms of conveyor. For instance, it can make specific suspended tray conveyor prototypes or load bars for hooking parts to be carried.